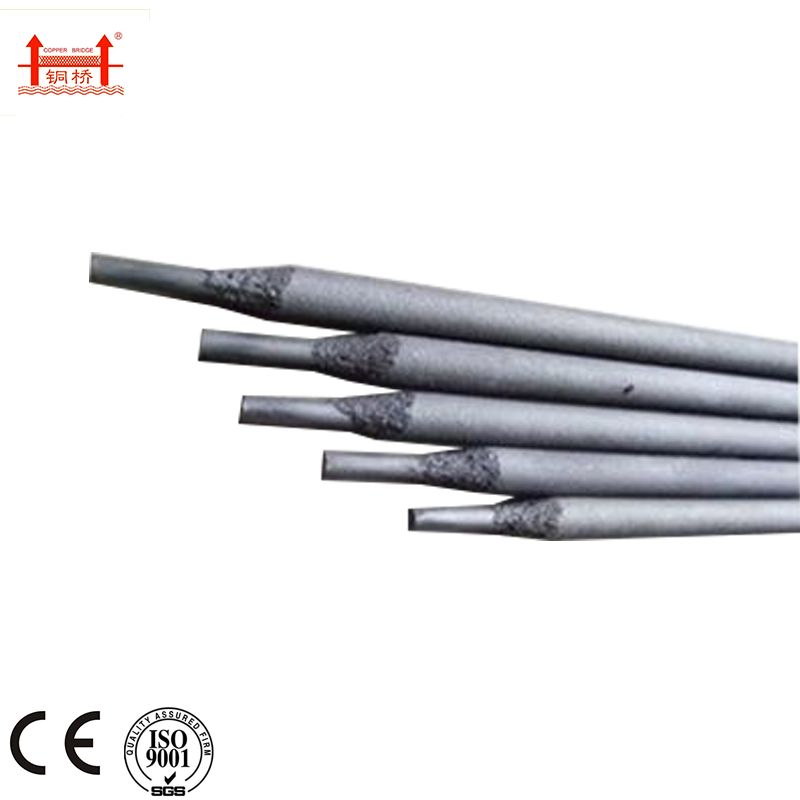

I-Stainless Steel Electrodes CB-A102

Isaziso sokusetyenziswa kwe-electrode yensimbi engenasici

1. I-chromium insimbi engenasici ine-corrosion resistance resistance (i-asidi i-oxidizing, i-asidi ye-organic, i-cavitation) , ukumelana nobushushu kunye nokuxhatshazwa kokugqoka.Ngokuqhelekileyo zisetyenziswa kwizityalo zamandla, iikhemikhali, i-petroleum kunye nezinye izixhobo zokusebenza.I-Chromium insimbi engenasici i-weldability engalunganga, kufuneka ithathele ingqalelo inkqubo ye-welding, iimeko zonyango lobushushu kunye nokukhethwa kwe-electrode efanelekileyo.

2. I-CR-13 insimbi engenasici inobunzima obuphezulu emva kwe-welding kwaye kulula ukuvelisa i-crack.Ukuba uhlobo olufanayo lwe-electrode yensimbi engenasici ye-chromium (G202, G207) isetyenziselwa ukuwelda, kufuneka ifudunyezwe ngaphezulu kwe-300 ° C kwaye ipholile malunga ne-700 ° C emva kwe-welding.Ukuba i-welding ayikwazi ukuqhutyelwa unyango lokushisa emva kwe-weld, ngoko ukhetho lwe-chromium-nickel yensimbi engenasici ye-electrode (A107, A207) .

3. I-Chromium 17 insimbi engenasici, ukwenzela ukuba kuphuculwe ukuxhathisa kwe-corrosion kunye ne-weldability kunye nokwandisa inani elifanelekileyo lezinto ezizinzileyo ezifana ne-Ti, Nb, Mo, njl., i-weldability ingcono kune-chromium 13 insimbi engenasici.Xa uhlobo olufanayo lwe-electrode yensimbi engenasici yechromium (G302, G307) isetyenzisiwe, kufuneka ifudunyezwe ngaphezulu kwe-200 ° C kwaye ishushu malunga ne-800 ° C emva kwe-welding.Ukuba i-welding ayikwazi ukuphathwa ngobushushu, ngoko ke ukhetho lwe-chromium-nickel ye-electrode yensimbi engenasici (A107, A207).I-electrode yensimbi engenasici ye-CR-NI inokumelana ne-corrosion elungileyo kunye nokumelana ne-oxidation, isetyenziswa kakhulu kwishishini lemichiza, isichumisi, i-petroleum, ukwenziwa koomatshini bezonyango.

4. 0 kwaye ngaphantsi ingasetyenziselwa yonke indawo-welding.

5. 0 nangaphezulu kwi-welding flat kunye ne-fillet welding.

6. I-Chromium-nickel yensimbi engenasici ine-titanium-calcium uhlobo kunye nohlobo oluphantsi lwe-hydrogen.Uhlobo lweCalcium titanate lunokusetyenziswa kwi-AC kunye ne-DC, kodwa ukungena kwe-AC ye-welding enzulu, ngelixa kulula ukubomvu, ukuze kusetyenziswe umbane we-DC.Ububanzi

7. I-electrode kufuneka igcinwe yomile, uhlobo lwe-titanium-calcium kufuneka lomiswe kwi-150 ° C ngeyure eli-1, kwaye uhlobo oluphantsi lwe-hydrogen kufuneka lomiswe kwi-200 ° C ukuya kwi-250 ° C ngeyure eli-1 (akukho kuphinda kumiswe, ngaphandle koko. i-coating ilula ukukrazula kunye ne-peel off) , thintela i-electrode yokunamathela ioli kunye nolunye ukungcola, ukuze unganyusi umxholo wekhabhoni we-weld kwaye uthintele umgangatho we-welding.

8. Ukuze uthintele ukubola phakathi kwamehlo okubangelwa ukufudumeza, i-welding current ayifanele ibe nkulu kakhulu, ngaphantsi kwe-carbon steel electrode malunga ne-20%, i-ARC ayifanele ibe yinde kakhulu, ukupholisa ngokukhawuleza phakathi kweengqimba, ukuba i-bead emxinwa ifanelekile. .

| Umzekelo | GB | AWS | Ububanzi (mm) | Uhlobo loKutyabeka | Okwangoku | Usebenzisa |

| CB-A102 | E308-16 | E308-16 | 2.5-5.0 | Uhlobo lweLime-titania | DC | Isetyenziselwa i-welding-resistant corrosion 0cR19Ni9 kunye ne-0Cr19Ni11Ti izakhiwo zentsimbi engenastainless ngaphantsi kwe-300︒C |

Ukubunjwa kwemichiza yeNsimbi egciniweyo

| Ukudityaniswa kwemichiza yentsimbi egciniweyo (%) | ||||||||

| C | Mn | Si | S | P | Cu | Ni | Mo | Cr |

| ≤0.08 | 0.5-2.5 | ≤0.90 | ≤0.030 | ≤0.040 | ≤0.75 | 9.0-11.0 | ≤0.75 | 18.0-21.0 |

IiPropati zeMechanical zeMetal eDiphozithiweyo

| IiPropati zeMechanical zeMetal eDiphozithiweyo | |

| Rm(Mpa) | A(%) |

| ≥550 | ≥35 |

Ukupakisha

Umzi-mveliso wethu

Umboniso

Izatifikethi zethu