-

Icingo lokuwelda elinoboya obukwaziyo ukunxitywa

I-Flux-core wire yaziwa ngokuba yi-powder-core wire, ucingo lwe-tubular, lunokwahlulwa lube ngamacandelo amabini okukhusela igesi kunye nokukhuselwa kwegesi.Umphezulu we-flux-core wire yenziwe nge-carbon steel low okanye i-alloy iron ephantsi kunye neplastiki efanelekileyo.Indlela yokuvelisa kukuba umgca wensimbi ugqitywe kwi-U-shaped section shape, emva koko i-powder ye-welding izaliswe kwi-strip yensimbi efana ne-U ngokomlinganiselo, kwaye umgca wensimbi ugqitywe ngokuqinileyo ngokusila, kwaye ekugqibeleni utsalwe. ... -

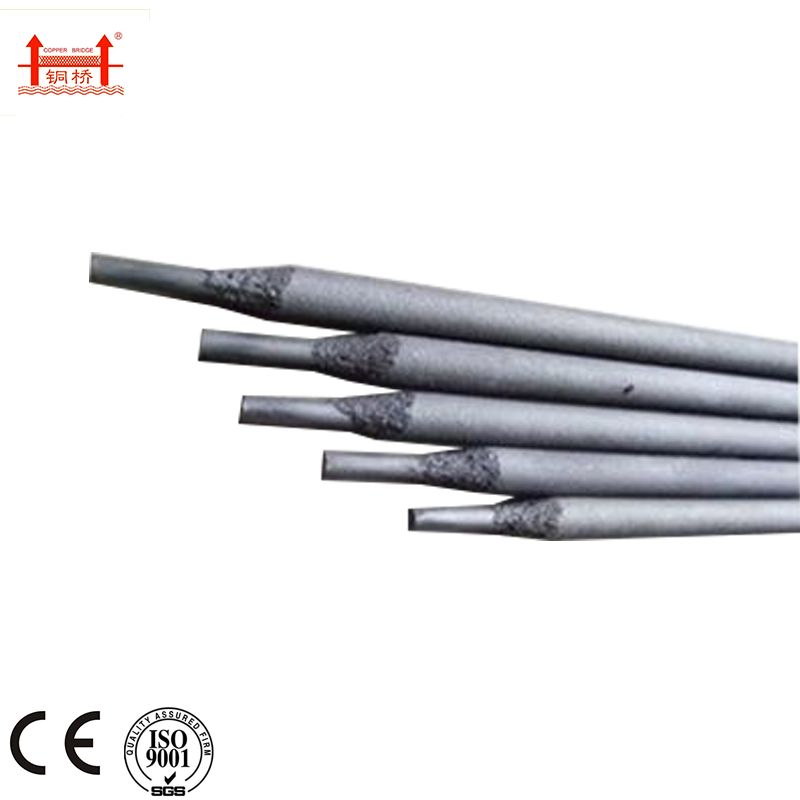

I-3.2mm ye-carbon steel welding electrode aws e7018 i-alloy steel electrode

I-CB-J507 yi-carbon steel electrode ye-iron powder kunye ne-hydrogen ephantsi kunye nohlobo lwe-potassium yesikhumba seziyobisi, ezinjongo ezimbini kwi-AC kunye ne-DC.ngenxa yokuba ulusu lweziyobisi luqulethe umgubo wentsimbi, ukusebenza kakuhle kokubekwa kunokuphuculwa.I-arc izinzile, i-splash incinci, i-slag ilula ukuyisusa, ukusebenza kwenkqubo kukuhle, iipropathi zomatshini zetsimbi ezigciniweyo zilungile, kwaye i-welding yendawo yonke inokuqhutywa.

Usebenzisa:Ifanelekile kwi-welding carbon steel kunye ne-low alloy steel structures, njenge-16Mn, njl.

-

I-Welding intonga ye-Welding ye-Carbon Steel Materials E6013 E7018

I-CB-J421 luhlobo lwe-carbon steel electrode kunye ne-titania yodidi.U-AC DC.Yonke indawo yokuwelda.Inomsebenzi obalaseleyo we-welding, ukusebenza okugqwesileyo kokusebenza, ukulawula okulula, i-arc ezinzileyo kunye nenkangeleko entle ye-weld.Ukusetyenziswa: Ukuwelda izakhiwo zentsimbi ephantsi kwekhabhoni, ilungele ngakumbi ukuwelda kwiipleyiti ezincinci kunye ne-cosmetic welding efuna amaso e-weld abe mahle kwaye abengezelayo.

-

2.5-5.0mm carbon steel welding electrode aws e6011

I-CB-J425 luhlobo lwe-electrode ye-carbon steel ene-cellulose uhlobo lwe-potassium yokwambathisa esetyenziselwa ngokukodwa ukuwelda ukuhla.U-AC DC.Inomsebenzi obalaseleyo we-welding, inkangeleko entle emva kwe-welding esezantsi ethe nkqo, ii-slags ezimbalwa kunye nokusebenza kakuhle kwe-welding.Ukusetyenziswa: Ifanelekile ukuwelda i-butt, i-welding ye-fillet kunye ne-lap welding kwiiplate ezincinci, ezifana nezakhiwo zetsimbi zekhabhoni eziphantsi njengemibhobho yezikhululo zamandla, i-air ducts, iitanki yeoli ye-transformer, i-hulls, iipaneli zangaphandle zeemoto, njl.

-

I-2.5mm encinci yokutshiza i-carbon steel welding electrode aws e6013

I-electrode yensimbi yeCarbon (amandla okuqina entsimbi efakiweyo ingaphantsi kwe-500MPa okanye i-50kgf/mm2) ifanelekile ukuwelda intsimbi yekhabhoni kunye namandla aphantsi entsimbi yealloy ephantsi.Kuhlobo lwe-hydrogen ephantsi kunye nohlobo lwe-electrode yomgubo wentsimbi, i-electrode kufuneka ihambe nge-350 ° C okanye ngaphezulu kokubhaka ngaphambi kwe-welding, ngaphandle koko, kuya kubakho iziphene ze-welding (ezifana ne-porosity, ukufakwa kwe-slag, iintanda, ukuwohloka kwenkqubo, njl. njl.) .I-electrode yodidi lweselulosi kufuneka ibhakwe ngokweqondo lokushisa lokubhaka... -

Plastic Metal Spool Gas Protection Copper Coated

Ukwazisa i-welding wire AWS ER70S-6, isisombululo esiphezulu kuzo zonke iimfuno zakho ze-welding.Nokuba ungumchweli ochwepheshile okanye umthandi we-DIY, olu cingo lwe-welding lwenzelwe ukuhlangabezana nazo zonke iimfuno zakho ze-welding ngokuchanekileyo nangokulula.Yenziwe ngezinto ezisemgangathweni weprimiyamu, olu cingo lwe-welding lwenzelwe ukuhambisa iziphumo ezithembekileyo nezingaguqukiyo.Nge-spatter yayo ephantsi, ukondla okugqwesileyo kunye nokusebenza ngokufanelekileyo, lukhetho olugqibeleleyo kuyo nayiphi na iprojekthi yokuwelda.Yenzelwe ukuba w... -

unikezelo lwe-electrode ye-welding steel stainless aws e308 e308l

TheweldmetalofE308/308Lisa19Cr-10Ni austenite microstructure equlethe limitedō ferrite.

-

unikezelo lwe-electrode ye-welding steel stainless aws e309 e309l

I-TheweldmetalofE309/309Iqulethe i-Cr Ni ngaphezu kwe-E 308/308L.

-

I-Stainless Steel Electrodes CB-A102

Isaziso sokusetyenziswa kwe-electrode ye-stainless steel 1, i-chromium insimbi engenasici ine-corrosion resistance resistance (i-asidi ye-oxidizing, i-asidi ye-organic, i-cavitation) , ukumelana nobushushu kunye nokumelana nokunxiba.

-

Ii-E316l-16 zentsimbi

I-electrode yensimbi engenasici inokwahlulwa ibe yi-chromium i-electrode yensimbi engenasici kunye ne-chromium nickel i-electrode yensimbi engenasici, ezi ntlobo zimbini ze-electrode ngokuhambelana nomgangatho wesizwe, zihambelana novavanyo lwe-GB / T983 -1995.Imiyalelo yokusetyenziswa kwe-electrode ye-Chromium yensimbi engenasici, i-chromium insimbi engenasici inokumelana nokugqwala okuthile (i-asidi ye-oxidizing, i-organic acid, i-cavitation) ukushisa kunye nokumelana nokubola.

-

I-Stainless Steel Electrodes E347-16

I-electrode yensimbi engenasici inokwahlulwa ibe yi-chromium i-electrode yensimbi engenasici kunye ne-chromium nickel i-electrode yensimbi engenasici, ezi ntlobo zimbini ze-electrode ngokuhambelana nomgangatho wesizwe, zihambelana novavanyo lwe-GB / T983 -1995.

-

I-Aluminiyam i-magnesium 5356 i-aluminiyam i-alloy argon i-arc welding wire

I-Argon arc welding wire isetyenziswa ngokubanzi i-ER309 wire okanye i-A302 electrode welding material.I-ER309 ucingo okanye i-A302 i-electrode imathiriyeli ilungele ukudibanisa ubulukhuni obuphezulu bentsimbi, ukulungisa isiseko sentsimbi yokubumba, ukwenza isiseko se-buffer sobundu bentsimbi ekhuniweyo, i-welding of crack, kunye ne-argon arc welding inokuhambelana okuhle kakhulu.Umgaqo weteknoloji ye-argon arc welding kukusebenzisa igesi ye-argon ukukhusela izinto ze-welding zetsimbi kunye nokunyibilikisa izinto zokuwelda kwisiseko se-welding nge-curre ephezulu ...