I-2.5mm encinci yokutshiza i-carbon steel welding electrode aws e6013

I-electrode yensimbi yeCarbon (amandla okuqina entsimbi efakiweyo ingaphantsi kwe-500MPa okanye i-50kgf/mm2) ifanelekile ukuwelda intsimbi yekhabhoni kunye namandla aphantsi entsimbi yealloy ephantsi.Kuhlobo lwe-hydrogen ephantsi kunye nohlobo lwe-electrode yomgubo wentsimbi, i-electrode kufuneka ihambe nge-350 ° C okanye ngaphezulu kokubhaka ngaphambi kwe-welding, ngaphandle koko, kuya kubakho iziphene ze-welding (ezifana ne-porosity, ukufakwa kwe-slag, iintanda, ukuwohloka kwenkqubo, njl. njl.) .I-electrode yohlobo lwe-cellulose kufuneka ibhakwe ngokweqondo lokushisa lokubhaka elichazwe kwinkcazo.Ukuba iqondo lokushisa lokubhaka liphezulu kakhulu, i-cellulose kwi-coating iya kutshiswa kwaye iimpawu zeteknoloji ze-electrode ziya kutshatyalaliswa.Xa usebenzisa i-electrode yohlobo lwe-hydrogen ephantsi, i-welder kufuneka iphile kwindawo yomoya, iqinise umoya wokungena komoya, ithintele ubungozi bokutshisa i-welding kumzimba.Amaxesha okubhaka e-electrode ephantsi yohlobo lwe-hydrogen akufanele adlule amaxesha amabini kangangoko kunokwenzeka ukukhusela i-coating ukuba ibe brittle kwaye iwe.

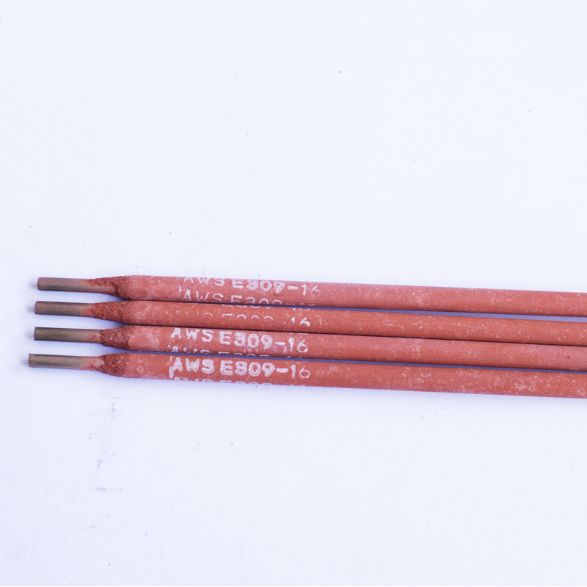

| Umzekelo | GB | AWS | Ububanzi (mm) | Uhlobo loKutyabeka | Okwangoku | Usebenzisa |

| CB-A132 | E347-16 | E347-16 | 2.5-5.0 | Uhlobo lweLime-titania | U-AC DC | Isetyenziselwa i-welding key corrosion ukumelana 0Cr19Ni11Ti intsimbi engatyiwa equlethe iTistabilizer. |

Ukubunjwa kwemichiza yeNsimbi egciniweyo

| Ukudityaniswa kwemichiza yentsimbi egciniweyo (%) | ||||||||

| C | Mn | Si | S | P | Cu | Ni | Mo | Cr |

| ≤0.08 | 0.5-2.5 | ≤0.90 | ≤0.030 | ≤0.040 | ≤0.75 | 9.0-11.0 | ≤0.75 | 18.0-21.0 |

IiPropati zeMechanical zeMetal eDiphozithiweyo

| IiPropati zeMechanical zeMetal eDiphozithiweyo | |

| Rm(Mpa) | A(%) |

| ≥520 | ≥25 |

Ukupakisha

Umzi-mveliso wethu

Umboniso

Izatifikethi zethu